A New Product Introduction:Edge Bending Flush Stair Nosing

Feb 07, 2022|

Feb 07, 2022| View:818

View:818The vinyl stair nosing products on the market are almost made by the same production process as vinyl floor: plastic extrusion and color paper wrapping. Therefore, they share similar advantages and disadvantages to the greatest extent. For vinyl stair nosing or tread, they are 100% waterproof and match vinyl floors in color.

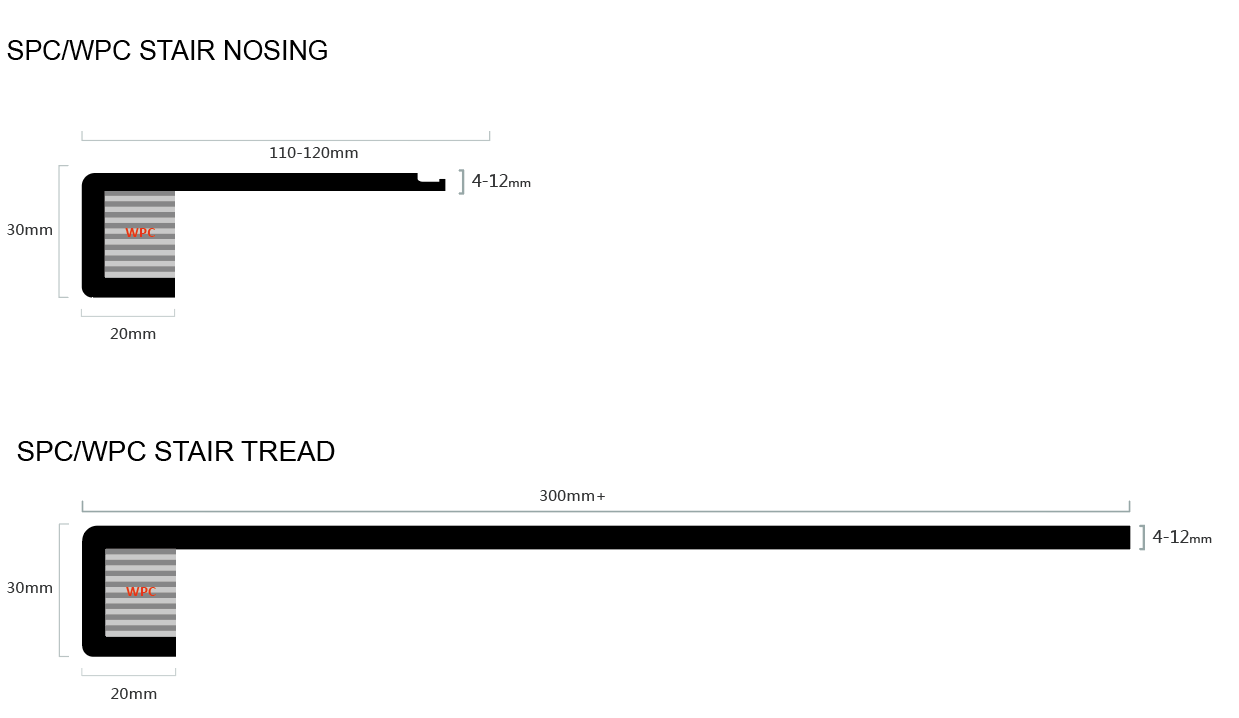

However, as mentioned, vinyl nosing is made by extrusion method in which the Mould plays an utmost role. For floor, the Mould can be used for all Vinyl floors of the the same thickness. But for vinyl nosing, the Moulds are different even if the nosing size or shape difference is minor, which always makes each new model’s price high. Therefore, we are developing a brand-new vinyl nosing which can lower the cost a lot and is more suitable for interior decoration compared with popular vinyl nosing, the edge bending flush stair nosing.

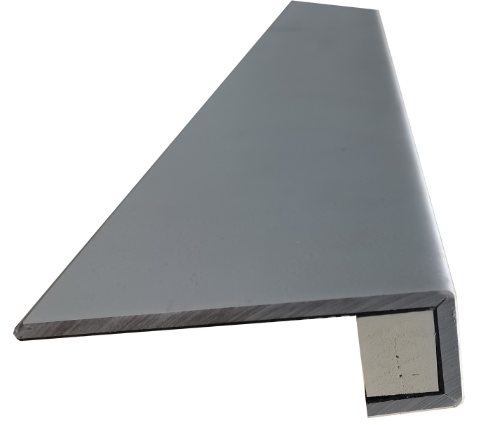

It’s actually made of finished vinyl floor by bending machine so it requires no extrusion mould. The nosing drop and stepping side size can be customized according to different designs. Since it’s floor in the first place, you don’t have to worry about if the color, thickness or click is fit. Even if the floor comes with underlay, the bending process is also okay. If you also need matching riser, the vinyl floor can easily provide them as they are just floor after cutting but before profiling process.

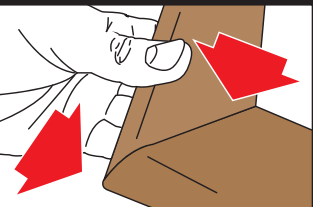

The nosing drop can be made square and round for different need. What’s more, the most attractive feature of this new type of nosing is it offers a not-so-bad solution to the stair edge finish. With 45 degree angle cutting, it would be like below, making a nice stair edge finishing.